![]() Highest Quality Parts

Highest Quality Parts

![]() Shop Now, Pay Later

Shop Now, Pay Later

Worldwide Shipping

All charges are applied in current currency Israel (EUR €)

€0,00 EUR

![]() Highest Quality Parts

Highest Quality Parts

![]() Shop Now, Pay Later

Shop Now, Pay Later

Worldwide Shipping

Eventuri

SKU:

Highest quality parts.

Highest quality parts.

Couldn't load pickup availability

"I recently bought a few performance parts for my BMW from AutoTopNL, and the whole experience was top-notch. The website was easy to navigate, and they had exactly what I needed. Shipping was fast, and everything came well-packaged. The quality of the parts is excellent—definitely not cheap knock-offs. My car runs smoother and sounds better already. Would definitely recommend AutoTopNL to any BMW enthusiast!."

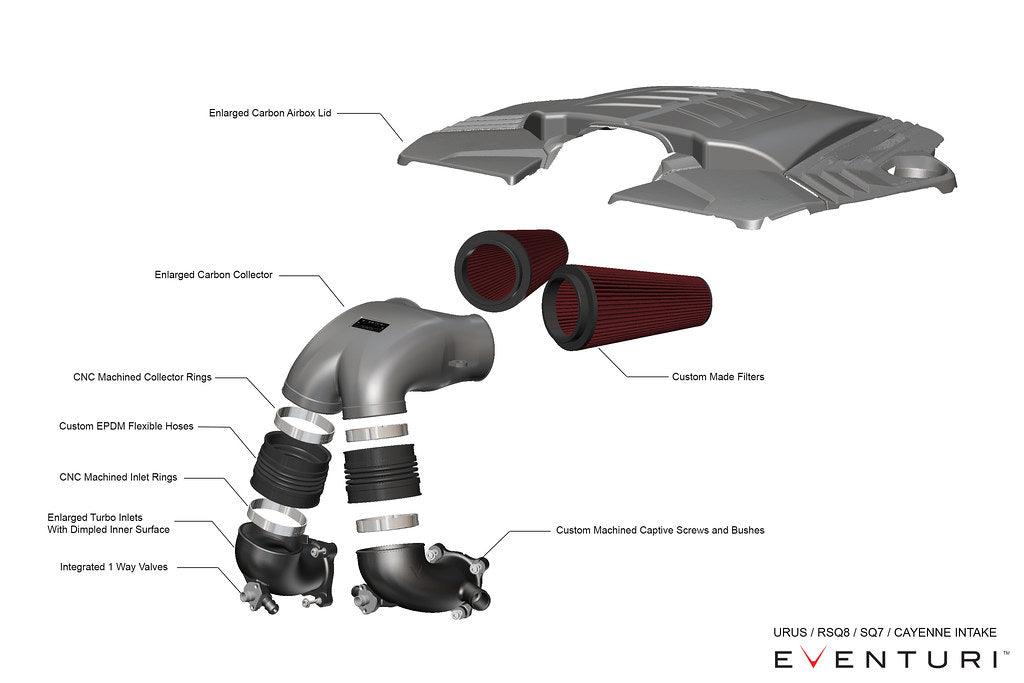

Performance Gain Stock Map: 14-20hp, 17-21ft-lb

Performance Gain Stage 1 Map*: 25-28hp, 20-23ft-lb

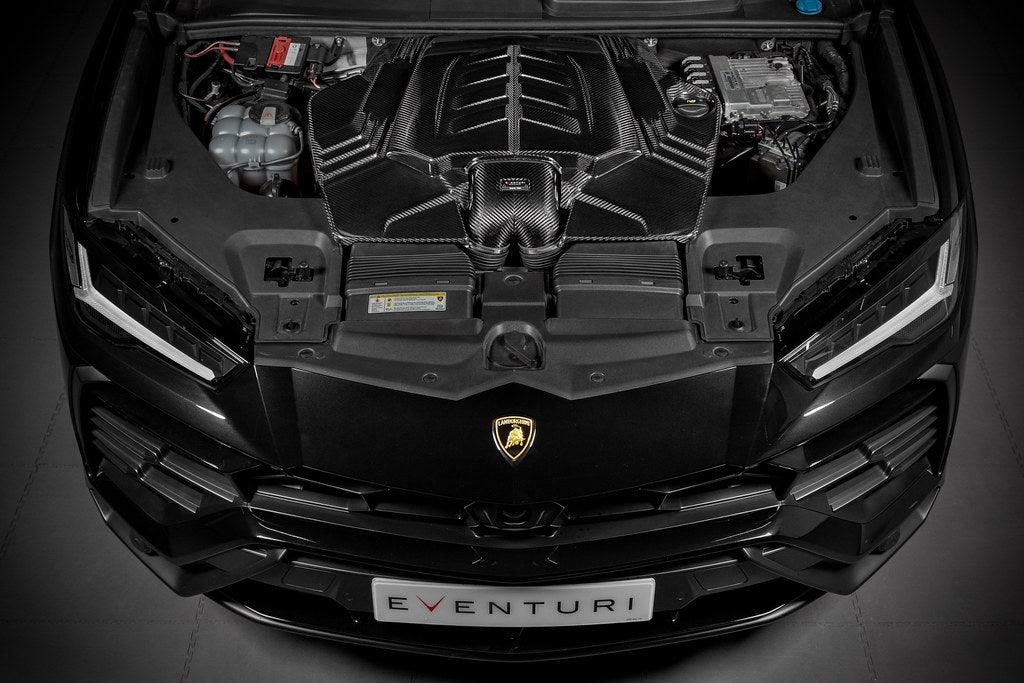

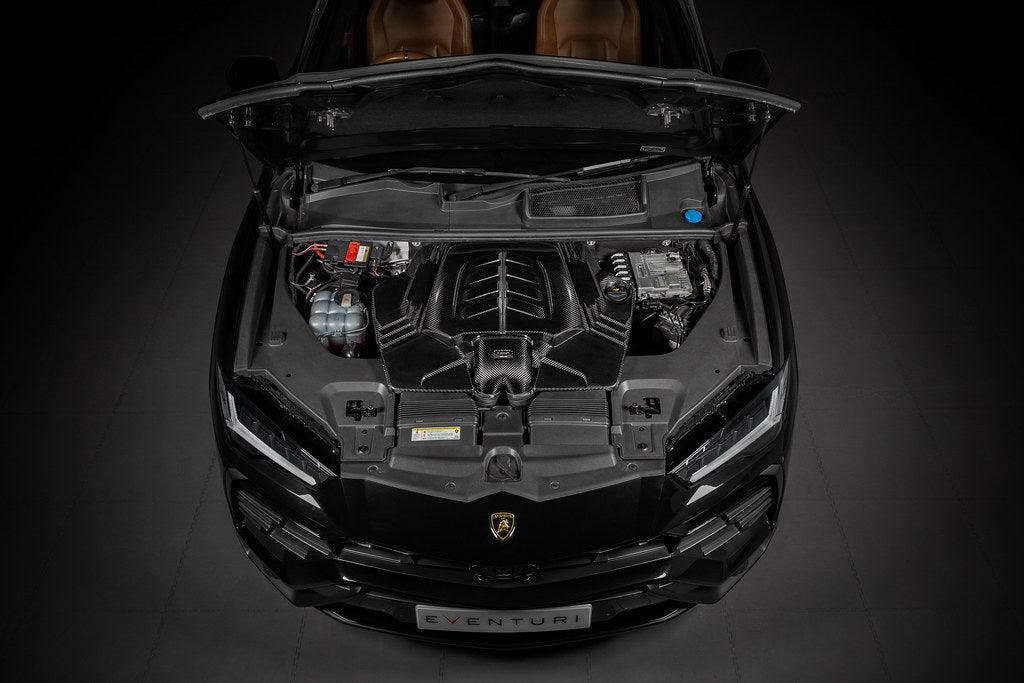

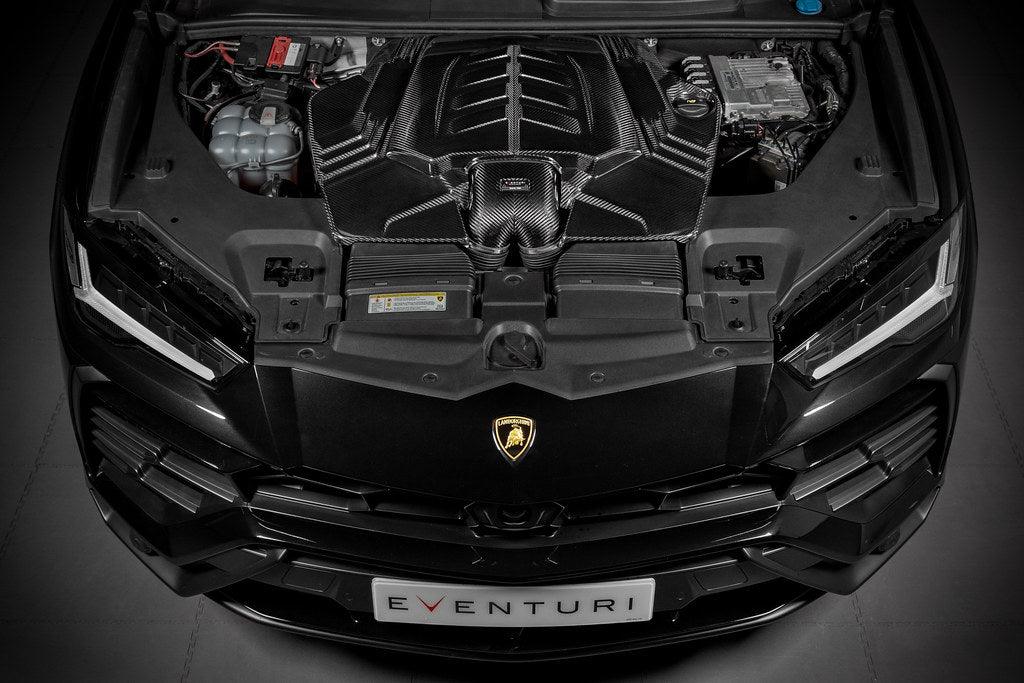

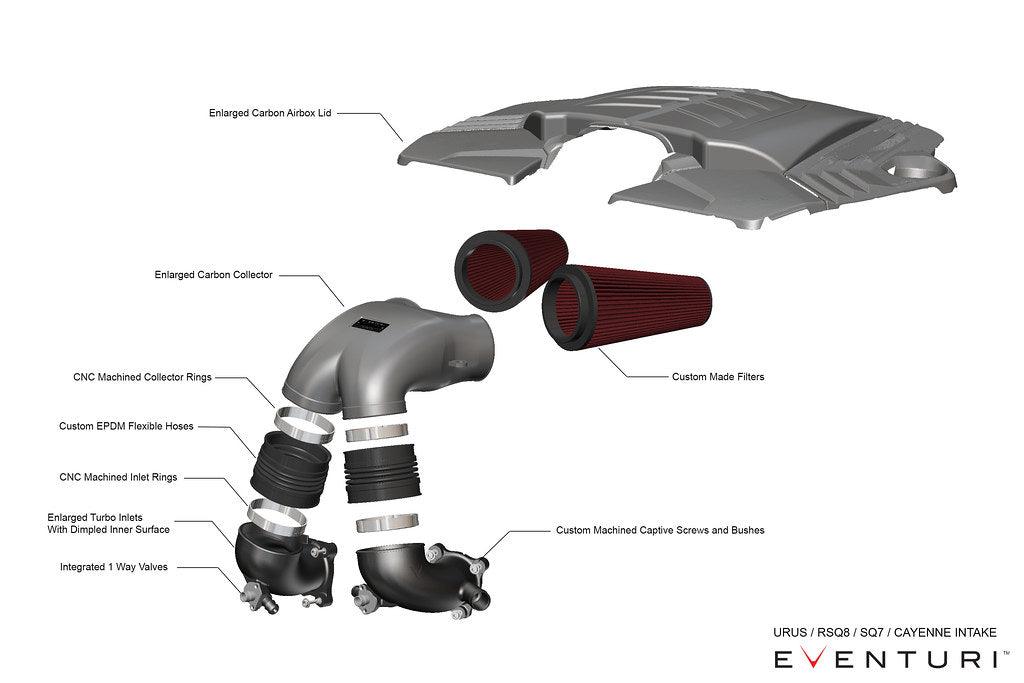

Fitment: 2020+ RSQ8/SQ7/SQ8, 2019+ Urus, 2020+ Cayenne Turbo, 2019+ Bentayga

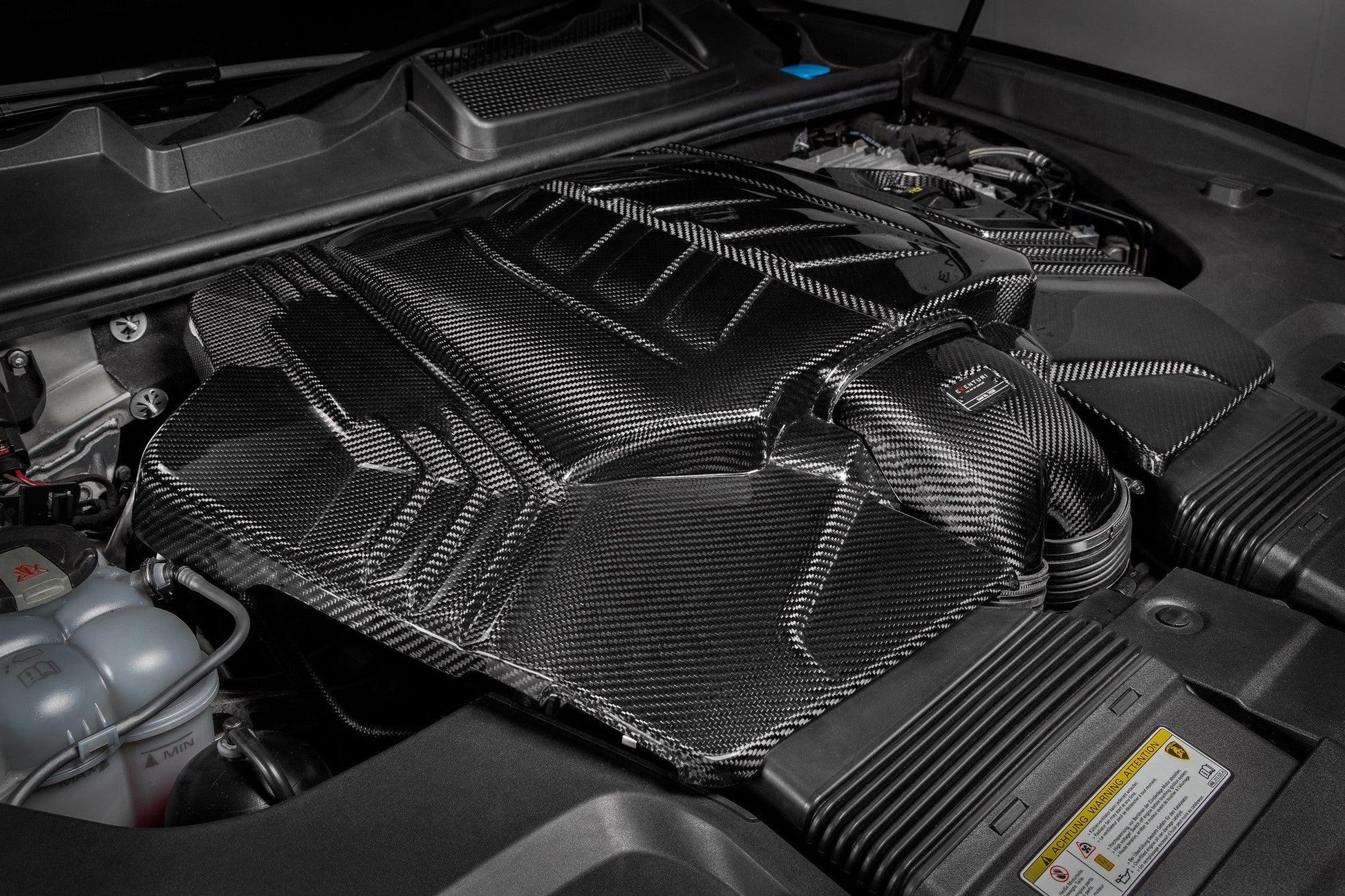

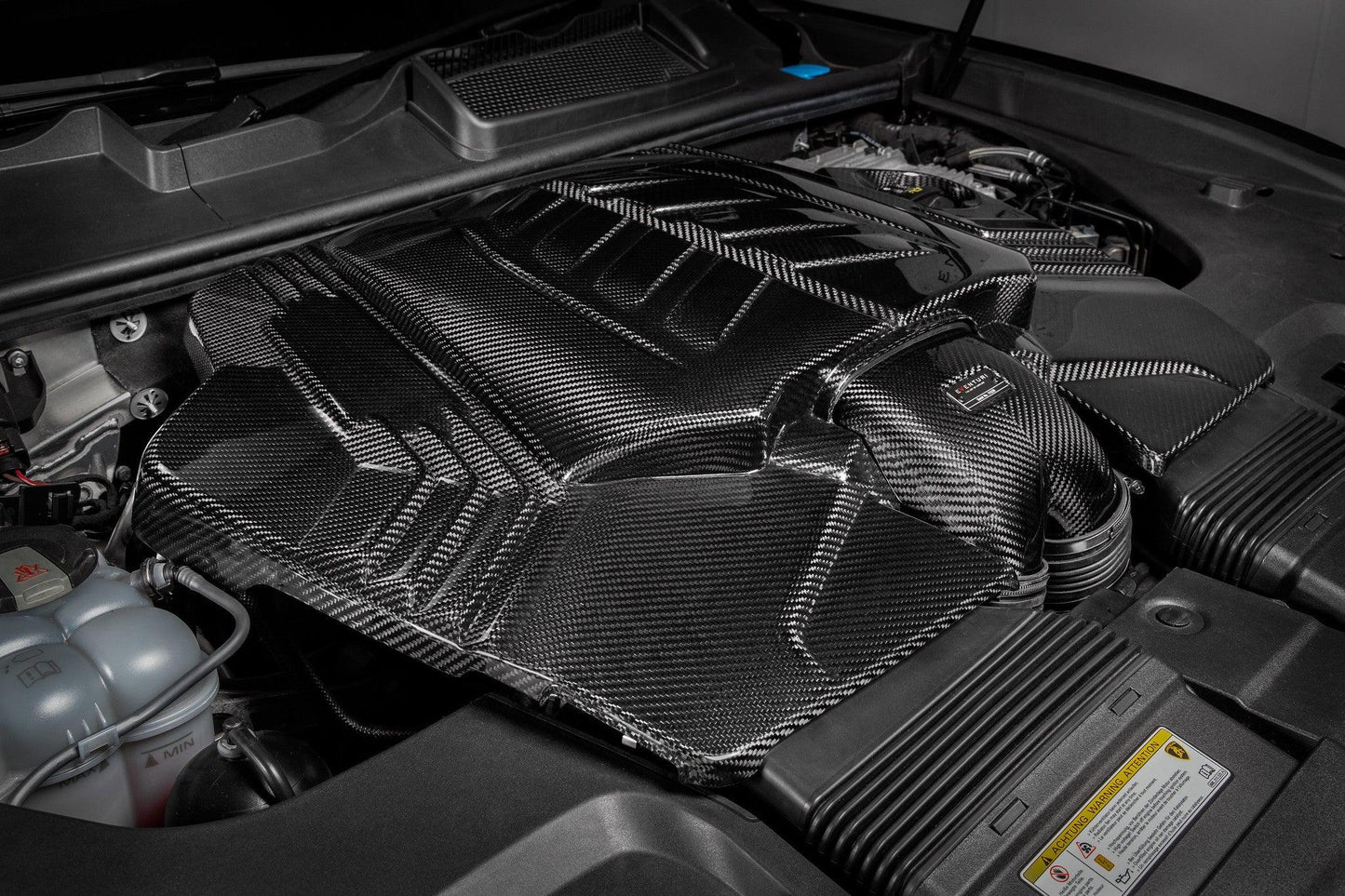

Our 4.0TFSI V8 EA825 intake is a ground-up redesign and optimisation of the entire air inlet track. Every component including the lid has been developed to allow the V8 twin turbos to pull in air with less drag resulting in industry leading performance gains. The stock airbox lid itself creates a restriction on the size of the flow collector which feeds the inlets from the filters. So we increased the height of the central section of the lid to allow for a larger flow collector and larger cone filters to be used. This removes the inherent restriction and sets our intake apart from the rest of the field who by utilising the stock lid must also use a restricted collector and filtration media. The turbo inlets are up to 43% larger in cross sectional area than stock and are designed with an advanced dimpled inner surface to reduce frictional losses between the flow and the wall boundary. By allowing a “cushion” of air at the wall surface, airflow is able to move through the inlets at higher flow rates with reduced pressure loss. This allows the turbos to draw air with less resistance and therefore reduce the wastegate duty cycle resulting in higher overall performance.

*Gains measured can vary with different ECU tunes.

Looking for more information? Just ask us.

Call Us: +31684454987

Email Us: autotopnl@gmail.com

Over 15 years of testing, fine-tuning, and perfecting performance cars expertise you can trust.

Every product is meticulously selected and road-tested by us to meet the highest standards of performance.

Proudly representing world-renowned brands such as Eventuri, Akrapovic, and Evolution M authentic, warrantied, and exclusive.

Performance isn’t just our business it’s our lifestyle. We help you unlock your vehicle’s true potential with precision and care.